Controls

niwatec GmbH develops and manufactures complete controls for various applications. Owing to their modular design, niwatec controls can easily be equipped with additional components. Also the replacement of already installed parts can easily be carried out due to the block design. In the correspondent submenu you will find more details on our well-established types of controls, as e.g. electro-hydraulic, gas, gas over oil or wellhead controls. Moreover we will be happy to submit you indiviual offers. Just contact us.

Our products satisfy even most sophisticated requirements concerning both reliability and functionality. This is guaranteed by our longtime experience in the international oil and gas and cavern storage industry as well as in the chemical, petrochemical, and power plant industry, and in the water and environmental technology. Also the high quality level of our component suppliers plays a major role.

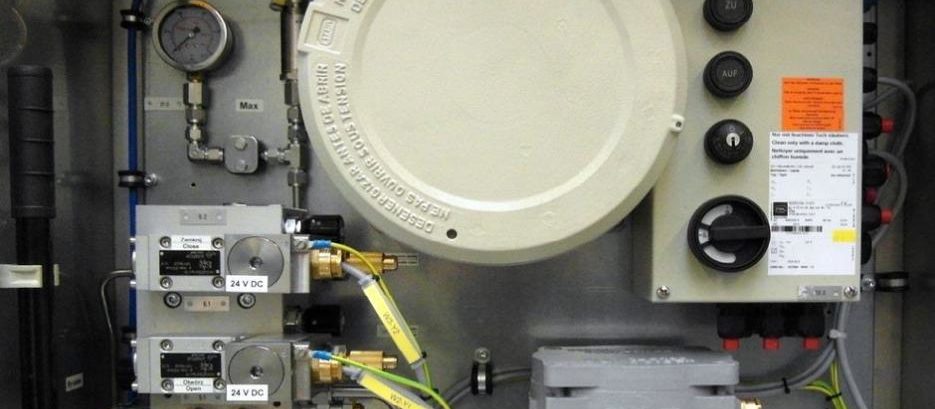

Electro-hydraulic Control

Together with our niwatec NWS Scotch yoke actuator or the NWLA linear actuator, our electro-hydraulic control guarantees a trouble-free and safe procedure during all kinds of operating conditions.

Oil is pumped out of the oil tank into the bladder or piston accumulator by means of an electric oil pump. Once the pressure needed for the unit is reached, the pump turns off automatically. Upon receiving a signal from the control, one of the two solenoid valves (either for opening or for closing the ball valve) opens the corresponding pipe and hydraulic oil pours from the accumulator into the hydraulic cylinder. The actuator drives and opens or closes the ball valve. In case of a power breakdown, one or more emergency strokes can be undertaken according to customer‘s specification.

Oil is pumped out of the oil tank into the bladder or piston accumulator by means of an electric oil pump. Once the pressure needed for the unit is reached, the pump turns off automatically. Upon receiving a signal from the control, one of the two solenoid valves (either for opening or for closing the ball valve) opens the corresponding pipe and hydraulic oil pours from the accumulator into the hydraulic cylinder. The actuator drives and opens or closes the ball valve. In case of a power breakdown, one or more emergency strokes can be undertaken according to customer‘s specification.

There are various possibilities to operate the unit:

- by remote signal from the process control system

- service directly on site (manual operation) using the control or the emergency manual override at the solenoid valve

- stroke with pressure from the bladder accumulator in case of power breakdown (emergency operation 1)

- by operating the hand pump (emergency operation 2)

The modular structure facilitates maintenance and the integration of security relevant components such as linebreak control systems, high-, low- or differential pressure pilots and ESD-valves.

Standard Features:

- operational pressure up to 250 bar

- for double or single acting actuators

- electric explosion protection according to Ex-e, Ex-d or Ex-ia

- CE and ATEX 94/9/EG certified

- control voltage: 24 V DC, 48 V DC, 110 V DC , 220 V DC or 115 V AC or 230 V AC

- temperature range: -29 °C to +50 °C

- control components mounted in stainless steel casing or – on request – on stainless steel panel

- tubing and fittings made of stainless steel, manufacturer of fittings according to customer‘s specification

- position feedback „open“ or „closed“

- manual emergency operation by means of hand wheel or hydraulic hand pump

- pressure switch for signalisation of minimum pressure needed

- local / remote switch (maintenance switch)

- bladder accumulator for emergency strokes (number of strokes according to customer specification) corresponding to PED, GOST, or ASME VIII div.1

Optional Features:

- extended temperature range: -60 °C to +60 °C

- low or high pilots for pipeline protection

- coils with low power consumption (approx. 3 W per valve)

- linebreak system (electric or mechanic)

- differential pressure switch (electronic or mechanic)

- ESD, Partial Stroke or SSV function

- regulating control systems

- profibus, modbus or foundation fieldbus interface boar

- redundant solenoid valves

- SIL 2 / SIL 3

- low regulating times (down to < 1 second) for single acting actuators

- control cabinet heating incl. thermostat

- cathodic separation

- fire protection

Pneumatic Control

Together with our niwatec NWS Scotch Yoke actuator, our NWRP Rack and Pinion actuator or our NWLA linear actuator, the pneumatic control guarantees a trouble-free and safe procedure during all kinds of operating conditions.

Together with our niwatec NWS Scotch Yoke actuator, our NWRP Rack and Pinion actuator or our NWLA linear actuator, the pneumatic control guarantees a trouble-free and safe procedure during all kinds of operating conditions.

Together with our customers, sophisticated solutions have been developed: SAV, HIPPS, standard open & close controls or position regulating systems can be implemented with high quality components. Our PNE pneumatic control can be equipped with a hand wheel or a hydraulic cylinder with hand pump, both working independently of the control.

Together with our customers, sophisticated solutions have been developed: SAV, HIPPS, standard open & close controls or position regulating systems can be implemented with high quality components. Our PNE pneumatic control can be equipped with a hand wheel or a hydraulic cylinder with hand pump, both working independently of the control.

The modular design facilitates maintenance and the integration of security relevant components such as linebreak control systems, high- or low-pilots, differential pressure switches or ESD-valves.

Standard Features:

- operational pressure up to 16 bar

- for double or single acting actuators (with spring reset)

- electric explosion protection according to Ex-e, Ex-d or Ex-ia

- CE and ATEX 94/9/EG certified

- control voltage: 24 V DC, 110 V DC , 220 V DC or 230 V AC

- temperature range: -29 °C to +60 °C

- control components mounted in stainless steel casing or – on request – on stainless steel panel

- tubing and fittings made of stainless steel, manufacturer of fittings according to customer‘s specification

- position feedback „open“ or „closed“

Optional Features:

- manual emergency operation by means of hand wheel or hydraulic hand pump

- extended temperature range: -60 °C to +60 °C

- low or high pilots for pipeline protection

- coils with low power consumption (approx. 3 W per valve)

- linebreak system (electronic or mechanic)

- differential pressure switch (electronic or mechanic)

- ESD , Partial Stroke or SSV function

- regulating control system

- pressure accumulator for emergency strokes corresponding to PED, GOST, or ASME VIII div. 1 (ARH or DPEM), certification depending on country of destination, number of strokes according to customer‘s specification

- pressure switch for signalisation of minimum pressure needed

- local / remote switch (maintenance switch)

- control cabinet heating incl. thermostat

- cathodic separation

- fire protection

Gas Control

With this type of control, solenoid valves lead the pipeline pressure directly into the cylinder, thereby opening or closing the unit. The amount of gas needed for regulation purposes is reduced considerably since gas or oil reservoirs are not employed. Furthermore, the actuators are more compact and weigh less than conventional gas over oil systems. niwatec‘s DG direct gas control can be equipped with a handwheel or with a hydraulic cylinder with hand pump, both working independently from the control.

The modular structure facilitates maintenance and the integration of security-relevant components, such as linebreak control systems, high-, low- or differential pressure pilots and ESD valves.

Standard Features:

- operational pressure upto 200 bar

- for double or single acting actuators (with spring reset)

- electric explosion protection in accordance with Ex-e, Ex-d or Ex-ia

- CE and ATEX 94/9/EG certified

- control voltage: 24 V DC, 48 V DC, 110 V DC, 220 VDC, 115 V AC, or 230 VAC

- temperature range: -29 °C to +50 °C

- control components mounted in stainless steel casing or by request on stainless steel panel

- tubing and fittings made of stainless steel, manufacturer of fittings according to customer‘s specification

- position feedback „open“ or „closed“

Optional Features:

- manual emergency operation by means of hand wheel or hydraulic hand pump

- extended temperature range: -60 °C to +60 °C

- low or high pilots for pipeline protection

- coils with low power consumption (approx. 3 W per valve)

- linebreak system (electric or mechanic)

- differential pressure switch (electric or mechanic)

- ESD, Partial Stroke or SAV function

- profibus, modbus or foundation fieldbus interface board

- redundant solenoid valves

- SIL 2 / SIL 3

- low regulating times (down to < 1 second) for single acting actuators

- pressure reservoir for emergency strokes corresponding to PED 97/23/EG, GOST or ASME VII Div. 1 (approval according to country of destination). Number of emergency strokes according to customer‘s specification

- pressure switch for signalisation of minimum pressure needed

- local / remote switch (maintenance switch)

- control cabinet heating incl. thermostat

- cathodic separation

- fire protection

Gas over Oil

Together with our niwatec NWS Scotch Yoke or NWLA linear actuator, our gas over oil control guarantees a trouble free and safe procedure during normal operation as well as in extreme situations.

With this type of control, solenoid valves lead natural gas into oil tanks.The gas pressure generates a hydraulic pressure on the oil cushion, opening or closing the valve by the aid of the Scotch yoke mechanism..

The modular design facilitates maintenance and the integration of security relevant components such as linebreak control systems, high-, low- or

Standard Features:

- operational pressure upto 100 bar

- for double acting actuators

- electric explosion protection according to Ex-e, Ex-d, or Ex-ia

- CE and ATEX 94/9/EG certified

- control voltage: 24 V DC, 48 V DC, 110 V DC , 220 V DC or 115 V AC and 230 V AC

- temperature range: -29 °C upto +80 °C

- control components mounted in stainless steel casing

- tubing and fittings made of stainless steel, manufacturer of fittings according to customer‘s specification

- position feedback „open“ or „closed“

- gas or oil reservoir certified according to PED, GOST or ASME VIII div. 1 (ARH or DPEM)

- manual emergency operation by means of hydraulic hand pump

Optional Features:

- extended temperature range: -40 °C upto +60 °C

- low or high pilots for pipeline protection

- coils with low power consumption (appox. 3 W per valve

- linebreak system (electronic or mechanic)

- differential pressure switch (electronic or mechanic)

- ESD or Partial Stroke function

- pressure accumulator for emergency strokes (number of strokes according to customer‘s specification) corresponding to PED, GOST, or ASME VIII div. 1 (ARH or DPEM)

- pressure switch for signalisation of minimum pressure needed

- local / remote switch (maintenance switch)

- control cabinet heating incl. thermostat

- cathodic separation

- fire protection

Well Head Control

Standard Features:

- for niwatec actuators type DA (double acting), SA (single acting) or other types

- pneumatic control upto 16 bar

- hydraulic control upto 700 bar

- bladder accumulator for emergency strokes (only for hydraulic controls, number of strokes according to customer‘s specification) subject to PED, GOST or ASME VIII div.1 specifications

- control voltage: 24 V DC, 110 V DC , 220 V DC oder 230 V AC

- Motorspannung: 24 V DC, 230 V AC or 400 V AC ~3 phases

- temperature range: -29 °C to +50 °C

- mounted in stainless steel cabinet

- regulating times according to customer‘s specification (down to < 1 second is possible)

Optional Features:

- underground safety shut-off valve control combined with above ground actuators

- extended temperature range: -60 °C to +60 °C

- coils with low power consumption (approx. 3 W per valve)

- ESD, Partial Stroke or SSV function

- pipeline pressure control by means of high or low pilot or linebreak system

niwatec GmbH offers high or low pilots as well as differential pressure switches for pipeline protection against overpressure or underpressure that may be integrated in the control. In case the pressure in the pipeline differs from the adjusted reference value, the pilot triggers off the opening or closing of the valve into the safety position.

niwatec GmbH offers two different linebreak systems. These systems ensure that in a case of average the joined actuator drives into the safety position. This completely automised procedure provides protection against further damages and subsequent accidents. The only difference between these two systems is the measuring method of the decrease in pressure.

The Mechanical Linebreak System is integrated into the control system and is independent from electric current. In case of average, this system overrides all other valves and therewith ensures that the actuator drives into the safety position.

The Electronic Linebreak System is equipped with additional transmission interface. Thus, various information can be transferred into the process control system. Like the mechanical linebreak, the electronic linebreak ensures that the actuator drives into the safety position in case of an average.